Strong and Easy

to Understand

and Install

Platform Hardware is thoughtfully designed to facilitate the secure connection of wood columns to beams. Its engineering ensures exceptional strength while maintaining simplicity in both comprehension and installation. This makes it an ideal choice for those seeking robust and user-friendly solutions for structural connections.

Anchor Options for Baseplate Installation

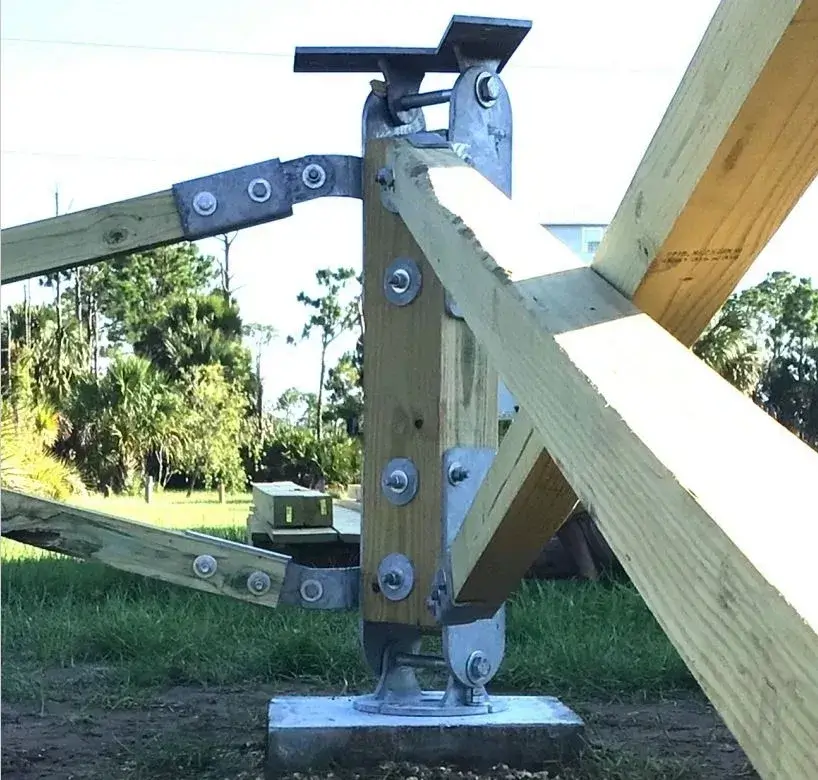

In this photo, you can see a baseplate securely anchored to a concrete footing. It's crucial to consider the soil's load-bearing capacity, the weight of the building, and any specific loads due to windy conditions when planning your footings. The baseplate comes with alignment slots, which are handy for maintaining a straight corner layout string line.

Additionally, there are four mounting holes that can be used to attach anchors to the footings. You have various options, including threaded epoxy rods, expandable bolts, and pour-in-place mounting bolts. Keep in mind that you should always refer to the anchor bolt manufacturer's size and depth requirements as a helpful guideline.

Fastening Techniques for Steel Shoe

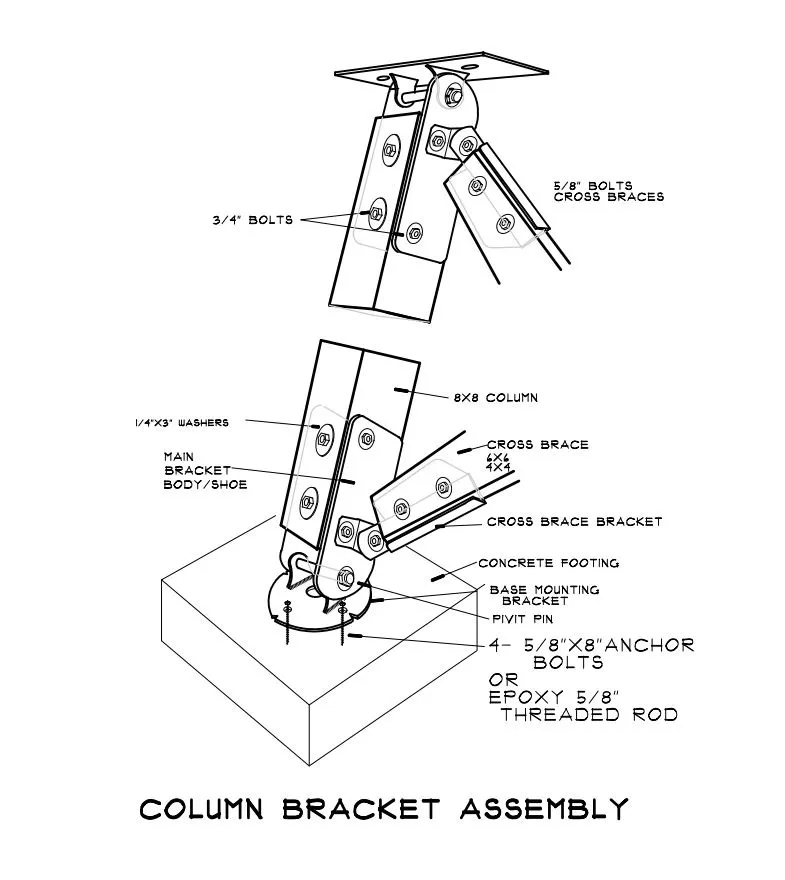

The 3 sided steel "Shoe" which holds the wood column is fastened to the baseplate using a bolt or a solid pin. This pivot or hinge allows the columns to be either vertical or at an angle to support the structure, and a wood column is connected to the Shoe by 3/4" bolts and large washers. The wood column sits on a shelf in the shoe to bear the load, both at the bottom and the top. The length of the wood column depends on the quality of the lumber grade and its compression and tension capacities. All wood columns should be piling grade and pressure-treated or better. Subject to the total loads and height of the building platform, it's holding.

Note! Chamfer the wood column edges to fit tight to the support shelf on the interior of the "Shoe".

The top header mounting bracket is fastened to the bottom of a beam or header by bolts that run through the beam and bottom plate of the building Wall assembly. The shoe is pinned to the top mounting bracket. This anchors the beam to the concrete footing as a continuous unit.

Lateral Bracing Options

Cross bracing is done using smaller shoes for 4x4's and 6x6's. The U-shaped brackets are fastened to the larger shoe with bolts. Solid rods can be used as bracing as well. Threading the end of a solid rod and using nuts can provide tension bracing, and multiple nuts may be required for holding strength

Design Criteria

Concrete foundations must account for factors such as soil quality, structural load, height, wind, and scour conditions. Considering local building standards, they should be designed by qualified professionals like engineers, architects, or designers. Similarly, the load-bearing capacity of wooden columns and bracing depends on lumber grade and safety factors. For example, treating piling grade yellow pine with a 1000 psi load can withstand 500 pounds per square inch (psi) with a 50% safety factor. An 8x8 column can handle 28,125 pounds, a 6x6 can handle 15,125 pounds, and a 4x4 can support 6,125 pounds.

Load-Bearing Capacity Assessment

The load-bearing capacity of the hardware, including the metal shoe, bolt or pin, and the base mounting bracket, was tested using a one-inch grade 1 bolt. The bolt sheared at 54,100 pounds, 56,580 pounds, and 60,230 pounds, with a safety factor indicating a one-inch bolt can safely hold up to 19,000 pounds as a working load rating. If a grade 5 bolt is utilized, the safe working load increases to 33,000 pounds.

Increasing the diameter to a 1 1/4-inch pin roughly doubles the capacity, reaching approximately 29,000 pounds for a grade 1. In the provided image, you can see the bottom mounting plate connected to the footing, a wood column attached to the metal bracket or "shoe" using bolts, cross-bracing brackets, wood cross-bracing, and a top header corner mounting bracket.

Guidelines for Beam Mounting

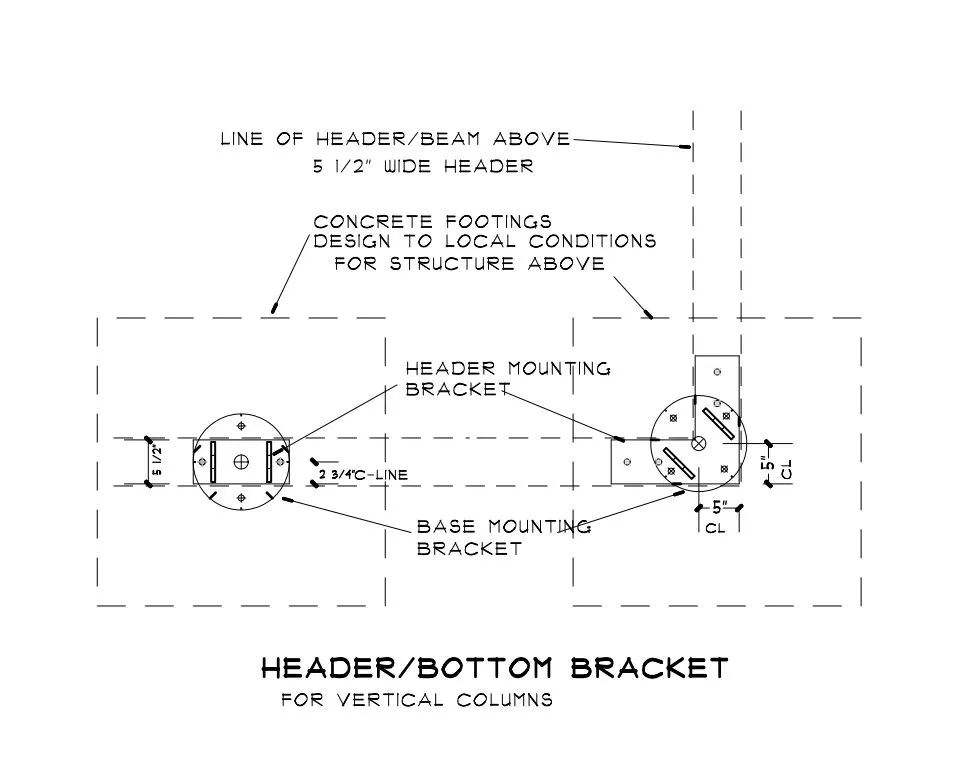

It is advisable to mark or stake out the exterior perimeter of the beam before determining the centerline of the base mounting bracket. In a corner installation, the centerline of the base mounting plate is typically located approximately 2 1/4 inches inside the centerline of the header or beam. To ensure precise alignment, it's recommended to pre-assemble a small section of the column assembly and verify the centerline layout.

In cases where angled columns are used, calculate the offset as 30% of the total height. For instance, if the total height from pin to pin is 100 inches, the offset would be 30 inches, subtracting the 2 1/4-inch offset to locate the centerline of the base mounting bracket.

Wood Columns

Various types of wood columns can serve as support columns, including telephone poles, tree trunks, or built-up timbers. However, it's essential to have a structural engineer verify their load-bearing capacity. The hardware, beams, columns, and bolts are all meticulously designed to be assembled, creating a robust raised platform foundation for constructing buildings or structures. Please note that the quality of lumber, bolts, and workmanship falls outside the hardware's performance responsibility.

The versatility of this hardware extends beyond residential use. It can be applied to decorative interior support columns, elevating structures above floodplains, constructing exterior water towers, bridges, creating raised platforms for mechanical HVAC systems, designing observation towers, and even building treehouses.

Terms & Conditions

Platform Hardware LLC, a Michigan limited liability company, provides a warranty to you as the original consumer purchaser. Products will be free from defects in materials and workmanship for one year from the date of purchase. This warranty is applicable to products that meet the following criteria:

They have been installed following the written installation instructions.

They have received appropriate treatment according to the building industry's recognized practices concerning storage, handling, and maintenance.

They have been exposed only to normal use. Any dents, scrapes, or other issues resulting from inadequate transport, storage, installation, or regular use are beyond my control and are not covered by this warranty.

They have not been installed in environments with high salt air content, corrosive chemicals, or other conditions unsuitable for galvanized cold-rolled steel.

Warranty Resolution and Coverage

Any implied warranties applicable to this warranty are limited to one year from the date of purchase. If you, the original consumer purchaser of any Platform Hardware, LLC product, believe that it is defective and falls under this warranty, please send a letter detailing the alleged defect, with postage prepaid, to the following address:

Platform Hardware, LLC

213 W. Main St., #4

Brighton, MI 48116

If, upon inspection by an authorized representative of Platform Hardware LLC, any product or parts covered by this warranty are found to be defective, Platform Hardware LLC has the discretion to repair, replace, or refund the purchase price. Please note that this warranty does not cover labor, installation costs, or any indirect or consequential damages of any nature. Connect with me for more details.